Enhanced oil recovery technologies

“NIIneftepromchim” JSC provides a mix of remedies to increase oil recovery and intensify oil production, ensuring maximum efficiency and profitability.

The technologies are aimed at optimizing the parameters of hydrocarbon production from productive layers and reducing the costs of long-term operated oil fields, involving non-draining and immovable oil reserves in the development.

“NIIneftepromchim” JSC has developed the technologies of:

-

Well treatment technologies with use of hydrocarbon composition of surface-active substances (hc surfactant)

- reagent SNPKh-9633 was developed for low formation temperatures (up to 60°С)

- reagent SNPKh-9640 was developed for elevated formation temperatures (60-105 °C)

Exploitation wells

Water control technology with use of HC surfactants (SNPKh-9633, SNPKh-9640).

The technology is designed to reduce the watercut for recovered products and increase the oil production enhancement for carbonate and terrigenous deposits with a high water cut (60-99%) and various mineralization of waters that drown an oil well.

The method is based on the blocking of water-saturated zones of the formation with high-viscosity emulsion systems, which are formed while pumping HC surfactant. Emulsions,appearing in the washed zones of the layer, are resistant to water erosion and are destroyed upon contact with oil, which ensures high selectivity of the method and does not impair the permeability of oil-saturated interlayers. In addition, the developed reagents have a hydrophobizing effect, are capable of dissolving and dispersing deposits of asphalts, resins, and paraffins and lowering the viscosity of the oil.

In the case of high well injection capacity (low injection pressure), it is recommended that a filler to be added to its composition to increase the efficiency of the use of HC surfactant. Its introduction allows increasing not only the formation rate of emulsion systems and their stability, but also the viscosity and strength. This contributes to the strengthening of blocking properties, decrease in susceptibility to depressions and a decrease in the possibility of emulsion removal from the formation.

Experience in application

Indicator SNPKh-9633 SNPKh-9633 with a filler

Number of treated wells more than 2 000

more than 900

Incremental oil production (tn per treated well) 1000 more than 1200

Daily average incremental oil rate (tn per day) 2,0-5,0 2-6,5 Reducing the volume of produced water (tn per treated well) more than 2000

more than 2500

Successful ratio morethan 70%

more than 75%

Action time morethan 1 year in terrigenous reservoirs, more than two years – in carbonate reservoirs

1,5-2,5 years Injection wells

Technology of HS SAS impact on the oil layer through injection wells.

The technology is designed to improve the oilfield performance in conditions of heterogeneous formations with different mineralization of oilfield and injected waters and high water cut of well production.

The method is based on the ability of the “hydrocarbon solvent-surfactant composition-mineralized water” reagents to form viscous, stable gel-like emulsions with an external hydrocarbon phase, which facilitates redistribution of the filtration streams and equalization of the displacement front in injection wells. This ultimately leads to water cut reduction of production and production enhancement in exploitation wells. In addition, the technology has a hydrophobizing effect and it is able to dissolve and disperse deposits of asphalts, resins, and paraffins, reduce the viscosity of oil.

Experience in application of the snpkh-9633 technology (114 oil zones):

- Incremental oil production – more than 2000 tn per treated well;

- Discovery ratio – 78%.

Advantages and differential characteristic of hc surfactant(snpkh-9633, snpkh-9640) and technologies based on them:

- low viscosity (usually 1,5 mm2/sec);

- low pour point (below minus550С);

- low interfacial tension on the boundary of water (10-2-10-4mN/m);

- surface-washing properties;

- promotes dissolution and dispersion of asphalts, resins, and paraffins;

- able to bind a large amount of water;

- impact selectivity;

- does not promote the swelling power of clays;

- delivery in a commodity form, does not require dilution

- use of standard oilfield equipment;

- no complications during injection and after well treatment.

-

The technology of impact on layers by means of polymer-hydrocarbon systems (SNPKh-PHS)

It is designed for conducting waterproofing works at exploitation wells and for redistribution of the filtration flows course in injection wells.

When interacting with water, it forms a rubber-like heterogeneous system. It has increased selectivity, i.e. when interacting with water, it forms a dense substance and blocks water-saturated reservoirs and subsequently it will be taken out during development of exploitation wells.

Advantages: selectivity, homogeneity, low viscosity, high adhesion, treatment time for 1 well does not exceed 6 hours, standard oilfield equipment is used.

Experience in application:

- number of treated wells — 120;

- technological effect inexploitation wells – 300-1500 tn of incremental produced oil with reduced water cut by 30-70%;

- consumption per 1 m of producing thickness is 0.5-1.5 tons

-

Backfill curing compound (SNPKh-3002)

The technology is used to seal the production strings and eliminate the inter-string flows.

SNPKh-3002 has a low viscosity, which allows it to be pumped into low-pore, low-permeability formations. The compound has a wide range of curing time, it is used at formation temperatures up to 90°С. The strength of this composition for bending, pressing exceeds the strength of cement stone, which allows it to be used to isolate sections of production strings subject to high depressions during operation of the wells.

Experience in application:

- quantity of processed wells – 150;

- Success – 80%.

-

The technology of directional acid treatment of highly watered layers (DAT of HWL)

The technology is designed to improve the efficiency of acid treatments in case of heterogeneous carbonate or terrigenous reservoirs with different mineralization of produced water at high water content (more than 80%).

The method is based on increasing the efficiency of acid treatments by blocking areas with increased permeability. The blocking of permeable zones is carried out with the help of viscous gel-like emulsion systems of the reverse type, being formed upon contact of the HC surfactant with mineralized waters that invade the well. The acid, being injected after that, will go not to areas with high permeability, but to oil-saturated low permeability areas not previously stimulated.

Experience in application:(43 treated wells):

- oil production enhancement by 1.5-5 times;

- incremental oil production – more than 800 tn per treated well;

- reduction of produced water volume– more than 1000 tn per treated well;

- average action time – more than one year;

- successful ratio – more than 70%.

-

Technology of acid solution modification for bottom hole treatment of wells with multi-functional additive SNPKh-8903

SNPKh-8903 is used as a multifunctional complex additive to the inhibited hydrochloric acid (it might be, in drilling mud acid) for its modification (upgrading) and preparation of acidic compounds.

The additive, which is a balanced composition, includes:

- retarding agent with a matrix of rock;

- mutual solvent;

- complexing agent;

- the mixture of surfactants, giving demulsifying properties to the composition and serving as an agent for dissolution of asphalts, resins, and paraffins

Advantages

- deceleration of the hydrochloric acid reaction with carbonate rock of the formation (24 % HCl concentration by 5 times);

- uniform penetration into high-and low-permeability zones of the rock, thereby increasing the radius of active drainage and involvement of the entire formation thickness in the development;

- preventing formation of emulsions and sediments upon the contact of the acid and formation fluids;

- inhibition of settling of sediment in the formation after acid-rock reaction;

- reduction of interfacial tension at the acid-oil contact boundary to 0.01-0.07 mN/m;

- minimum costs for the preparation of acid composition. The acid composition can be prepared directly at the well.

Experience in application:

- about 400 well treatments;

- specific efficiency of the technology application is more than 300 tons of oil per 1 treated well;

- the average oil production enhancement per 1 well is more than 2.0 tn/day

- the average action time is more than 10 months;

- the success rate forexploitation well treatment is more than 85%.

-

Stabilizer of iron ions SNPKh-8905

SNPKh-8905 is intended for stabilization of iron ions in technological processes of acid treatment of bottom-hole zone

SNPKh-8905 restores trivalent iron ions to bivalent

The reagent consumption rate in the acid composition is:

- 0,8 – 1,0 % об. (5000 ppm Fe3+)

- 0,5 – 0,7 % об. (2500 ppm Fe3+)

Advantages

- low pour point (below minus 50°С);

- prevention of settling of sediment and formation of stable emulsions with formation fluids

- retention of reservoir properties of the productive formation;

- applicable in combination with other components of acid composition and in hydrochloric acid of different concentrations;

- standard oilfield equipment is used.

-

Technology for improving carbonate reservoir productivity with the use of reagent SNPKh-9010

The technology is designed to improve well productivity in carbonate reservoirs.

Applied composition of SNPKh-9010 includes a mineral acid, a retarding reagent for the carbonate component of the formation, solvent-homogenizer, surfactant and corrosion inhibitor. As a result of low reaction rate with rock, the composition provides enlarging of active drainage radius of the formation, partial dissolution of the rock matrix and cleaning of pore channels from asphaltene-resin-paraffin deposits, mechanical impurities and clay particles.

Oil production of the well enhances by 1-6 tn/day, incremental oil recovery after 1 well treatment is not less than 450 tn. Initial water cutting of well production is up to 40%.

Standard oilfield equipment is used for well treatment.

The reagent is produced in an industrial environment and is delivered by railcars

The tubing is lowered into the well to the level of the lower perforation holes. A packer is installed above the perforated interval. The reagent is pumped into the well at the rate of 1.5-3.0 m3 per 1 meter of the penetrated thickness. The reagent is pressed into the formation by oil or water. After 16 hours, the final work is carried out, the oilfield equipment is lowered and the well is put into operation.

Requirements that should be taken into account upon sale

- Carbonate-containing porous type collector.

- History of previous treatments (type of exposure, effectiveness).

- Formation pressure –not lower than 0,6original pressure.

- Water cutting of well production – not higher than 40% (watering with formation water). In case of higher water cut, reagents for temporal blocking of water supplying sublayers (SNPKh-8700) are injected before acid treatment.

- Initial oil saturation according to geo-physical well logging – not less than 60%.

- Perforated thickness is not less than 2 м.

- Presence of remaining recoverable oil reserves is not less than 30%.

- A jumper to the underlying water-bearing horizon is not less than 5 m.

- Frequency of hydrochloric acid treatment – not more than 2. In case of high multiplicity, the compositions for equalization of the injectivity profile and temporal blockage of the flushed zones or commercial oil in a volume equal to the volume of previously injected acid compositions shall be previously injected.

Experience in application:

The main exploitation targets Tournaisian and Bashkir tiers Bashkir tier, Vereiskian strata Bashkir tier, Vereiskian strata С2 Kashirskian-Podolskian strata Treated wells, units 484 300 100 208 Incremental oil production per 1 treated well 1270 600 – 1000 (917)

1560 860 Successful rate, % 93 85 92 90 Average incremental oil rate, tn per day 2,2- 3,2 1,6 – 2,7 3,8 2,35 Accumulated incremental oil production for the period, thousand tonns ̴ 650,0 275,1 156,0 179,8 -

Technology of borehole zone of injected and exploitation wells in clogged-up terrigenous collectors (SNPKh-9021 and SNPKh-9022)

The technology is intended for deep processing of low-permeability clay-containing reservoirs and is based on the ability of the reagent SNPKh-9021 to maintain its activity while deep penetrating into the formation and gas cutting of fluid when reacting with SNPKh -9022 reagent.

The effect of the application is achieved by:

- enlarging the active drainage radius of the formation as a result of partial dissolution of the solid matrix and dispersion of clay particles

- cleaning of pore channels from asphalt, resin, and paraffin deposition, mechanical impurities and clay particles

- dehydration of the bottom hole zone of exploitation wells

- decrease in interfacial tension at the oil-water boundary.

Specifications

Brand SNPKh-9021 SNPKh -9022 Appearance liquid from colorless to light brown color turbid liquid upon settling, setting of white sediment while settling Density at 20°С, kg/m3 1000-1100 Not less than 1080 Dynamic viscosity at 20°С, mPas Not more than 5 Steel dissolution rate (st.3) at 20°С, g/m2, not more 0,35 The method is implemented for exploitation and injection wells.

The treatment of the bottom hole zone is performed using standard oilfield equipment.

The technology allows increasing the productivity factor of exploitation wells by 2-10 times and the injectivity index of injection wells by 2-4 times.

-

Emulsion-based well-killing fluid

Emulsifier SNPKh-9777 is intended for the production of invert emulsions, used:

- for oil and gas wells killing;

- as a basic reagent for preparation of process fluids used in enhanced oil recovery processes and for well workover;

- when developing oil and gas condensate fields at any stage of waterflooding in order to increase oil recovery of formation,

- for temporary isolation of high-productive watered interlayers before acidic bottom-hole treatment, allowing to act on the low-productivity reservoir.

Advantages

- reservoir quality retention of the productive formation;

- Well starting operation in the shortest possible time, without loss of oil production rate, with a possible reduction in water cut of the product;

- regulation of the density of well-killing fluid in a wide range from 1.0 to 1.6 g/cm3

- thermal stability up to 90 ° С

- high sedimentation resistance.

The emulsion-based well killing fluid is an invert emulsion:

- dispersion medium – hydrocarbon solution of Emulsifier SNPCH-9777

- dispersed phase – water, mineralized with various salts.

The viscosity and density of the well killing fluid is controlled by the phase ratio and the degree of water mineralization.

-

Process upgrading of integrated impact on formation

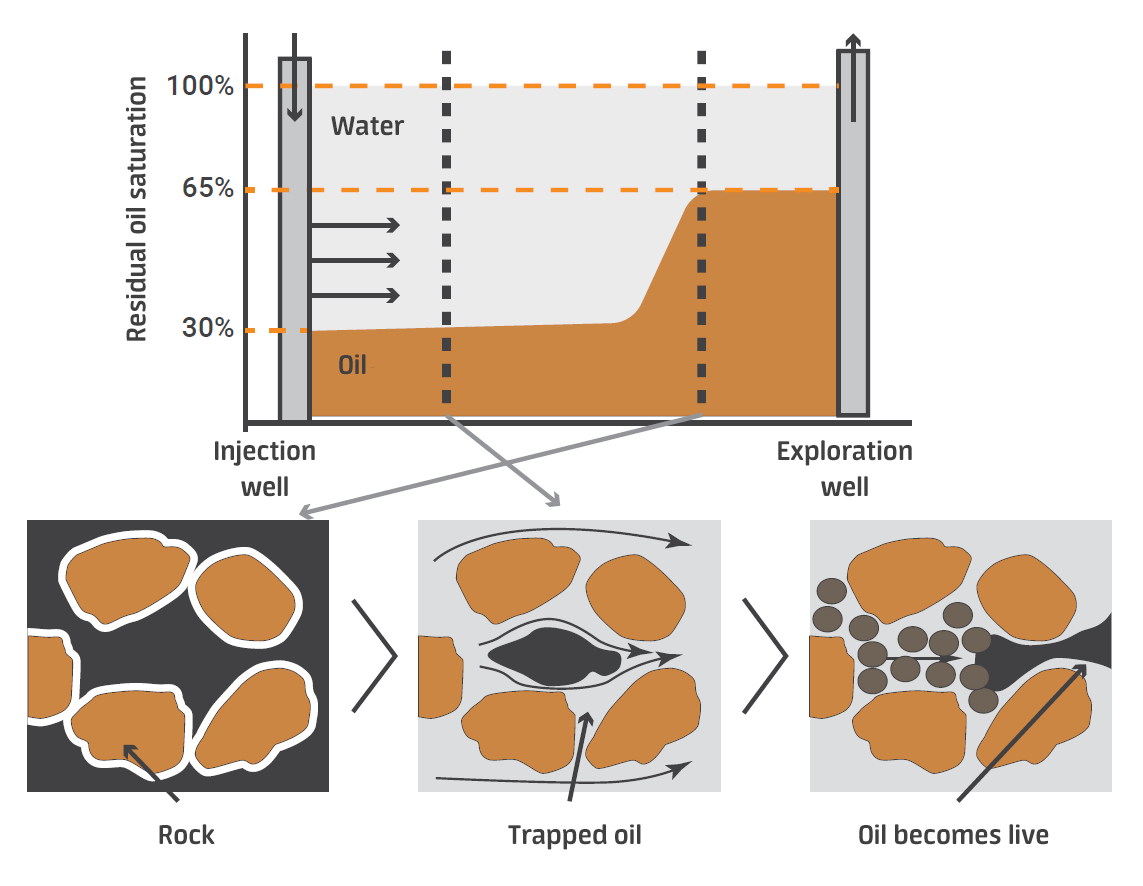

The technologies are designed to involve undrained oil reserves in the development due to the increase in the formation coverage with waterflooding followed by an increase in oil displacement capacity of injected water.

The essence of the technology is to expand the conditions of application and increase the efficiency of processing by using the optimal combination of surfactants of different nature, the concentration of components, as well as the dispersity of working agents in the oil-displacing and blocking systems.

The technology is characterized by the fact that a micellar composition with high oil-removal properties is used as a surfactant composition, and a polymer and fine aggregate are used as a polymer-disperse system.

Experience in application

Technology Total number of treated sites Incremental oil production, thousand tons SNPKh-95 49 196,3 PG-UVS 53 190

-

Chemical treatment with sonocatalizer

The technology is based on a combination of chemical and physical methods of oil recovery enhancement.

The use of chemical reagents and physical fields allows achieving a synergistic effect: significantly increase the efficiency of treatment.

The innovative method involves injection acid composition (SNPKh-9010ZH, 9021 (9030) or hydrochloric acid modified by the additive SNPKh -8903A) into the formation and treatment with acoustic waves.

Combined application allows:

- Increase the penetration of acid composition into the formation by several times;

- Reduce the surface tension at the “oil-water” and “oil-rock” boundaries, increasing oil fluidity;

- Activate under control the chemical reaction in the zone of acoustic influence.

Depending on the characteristics of the treated wells, it is possible to use ultrasonic acoustic waves, as well as acoustic impact waves.